Go to the

Archive index

Go to the

Archive indexClip-on cyclemotors seem to be the children of great wars. This may come from a general demand for immediate, cheap transport or a call by ex-conscripts for personal wheels that will take the owner where and when he wants. Either way, designers met the demand with engines which reflected national experience. The Brits gave us rather crude two-strokes with horrible transmissions. Italy responded with little gems like the Cucciolo which set the pattern for generations of Ducati competition bikes. In France the VéloSoleX honed the skills of generations dodging its wobbling progress. And then there was Bugatti...

Ettore Bugatti was Le Patron, the absolute boss of his factory at Moisheim, near Strasbourg. However, he never lost contact with Paris and, in 1916, rented an apartment in rue Boissieres, a suitably fashionable address, which he kept until his death more than thirty years later. Between the wars Bugatti acquired a showroom and a service department on the edge of the city. From the 1930s Ettore was Paris-based, primarily to maintain contact with key railcar customers. This came in useful when industrial unrest spread through France. In 1936 there was a strike at Moisheim and Le Patron was barred from his own factory. In a fit of pique he abandoned Moisheim to a management team led by his son Jean and paid only the briefest visits thereafter.

After Ettore Bugatti's departure in 1936 from Molsheim in Alsace for Paris he embarked on an orgy of drawings for possible and implausible engines. During WW2, Bugatti and his staff led a peripatetic life in Paris with the old service premises at Levallois, previously the La Licorne factory, earmarked as a design, development and ultimately production shop. The Paris presence expanded during the war with larger design facilities and workshops. Castings and probably quite a lot else were to be subcontracted but there were the makings of a viable business.

During the war, Ettore worked on new products for the post-war market, mostly far smaller than his traditional super-sporting products and it has been claimed that these represented a rationalised range. However, this is true only in a limited sense, for though the designs are related there appears to be no commonality, in production terms, between them. The new family was to comprise the T68, an enchanting miniature car driven by a 370cc four cylinder, four valve blown engine: the T72 cyclemotor, and the T73, based on a neat twin-cam 1.5 litre four cylinder engine but offered in various manifestations. While Noel Domboy, a close friend of Bugatti, claimed that he and Edward Bertrand designed the T68 engine before following Bugatti to Paris, it seems more likely that it was the first of the new Bugatti-designed range.

Some common design themes run through the designs, notably detachable heads, an un-split crankcase with the crank inserted from one end and drive by a train of pinions - of the sort referred to in the GP Delage as 'Une veritable cascade des pignons' - to overhead cams worked through bucket tappets. There was a cheerful inability to finalise a design: both the T68 and T72 were stretched as 'B' versions during development while the T73 could appear as a single or two OHC unit, blown or unblown with three or four valves per cylinder. However, a 10.6 or 12.66cc air-cooled single doesn't really fit anywhere. There was no sign of component standardisation as in the Rolls-Royce B series conceived at much the same time.

The range only makes sense in a political context. In 1940 and 1941, when conceptual work on the cyclemotor must have started, bets were on Germany winning WW2. Bugatti needed new projects: his beloved elder son Jean had died a year earlier and he had lost Moisheim first to the trade unions and then to the Germans. Although he was only 59 he had heart trouble, hence perhaps an orgy of new projects, some of them ill-advised.

The only truly common theme in the new range was small size and presumably fuel economy since he had deduced, correctly, that whichever side won expensive, rationed petrol and post-war regulations and taxes would make big cars extinct. On this basis the proposed range was perfectly rational. The T73 and derivatives might have been a profitable answer for road use and small sports cars and voiturette racing. The T68B might have been noisy but tremendous fun as cheap to run road transport (although, no doubt, frightfully expensive compared to the simple Citroën 2CV with similar engine size to be launched shortly after the war). The hyper-complex cyclemotor could have been, in the later words of Ricart of Pegaso 'a jewel for the rich' and a portable demonstration piece for Le Patron's skills. Given the availability of cheap skilled labour it all made sense at the time except for production costs.

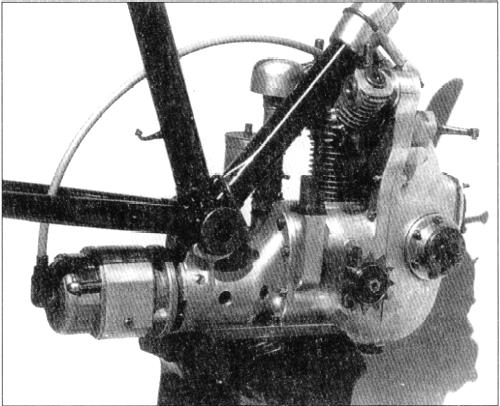

A complete T72 on a non-Bugatti bicycle.

The correct rear mounting clamp is not fitted.

Note the adjustable chain tensioner built as part of the main

costing.

We are fortunate in being able to study drawings and photographs at the Bugatti Trust together with engine components. Bugatti followed his usual design approach of working in soft pencil and then giving his sketch to be worked up by the design draughtsman: the EB personal logo appears on the sketches but drawings are anonymous. This formal practice was usual at the time before the barbaric Brits introduced the technique of first track design, otherwise known as 'Tack it on there, Boy' and letting John Cooper tell a researcher that there weren't any surviving drawings - 'We washed the wall years ago.'

The original T72 had 22mm bore and a capacity of 10.6cc. There is probably no 72A, since 'B' most likely stands for 'bis', literally 'twice' but also 'the second one', a usage which is common Bugatti practice. The crankcase is a single light alloy casting which forms the heart of the engine with all accessories built into or hung from it, which also acts as a reservoir for a pump and squirt lubrication system. The final drive clutch, worm and wheel are also mounted on the main casting with a ratchet and chain drive to the cycle chainwheel. A chain tensioner is fitted. Bugatti designed at least some cycle parts to match: a transmission drawing shows most elegantly curved pedals but no other drawings seem to have survived.

A subtle point is that both engine and pedal power use the variable ratios already provided on the bicycle, probably by an epicyclic hub. A great improvement on the single speed friction roller used by the Brits which allowed engine power to drop off just when it was most needed: as speed fell on a hill, for example - all too reminiscent of a Ford suction wiper or a single speed de Dion tricycle.

The cylinder head is a single alloy casting which includes a pair of camboxes and the bucket tappets acting on a pair of minuscule valves and springs - there would hardly have been room for four valves in that tiny head. The air-cooled steel barrel is entirely conventional, spigoted into crankcase and head.

There are tantalising drawings of a carburettor with integral float chamber built in to the crankcase. This is reminiscent of much earlier wick carburettors. A photograph of a fully built up machine shows, however, a conventional small Solex. However, the most striking feature, for a utilitarian engine, is the supercharger - a Roots blower, driven from the central train of pinions, with a pair of intermeshing three lobed rotors - an arrangement of dubious value - and which looks very like a scale model of any pre-war Bugatti supercharger. The magneto specified is a MF Speciale.

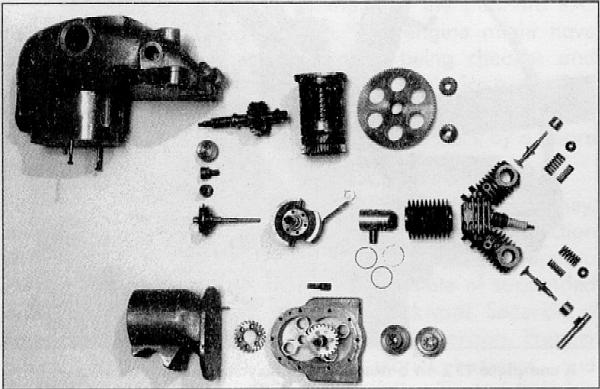

The Bugatti Trust's T72 dismantled: the 22mm diameter piston

gives the scale.

This shows the large central pinion in the valve train

and the complex clutch and worm and wheel final drive.

Roots supercharger is at centre right.

The roller bearing connecting rod is fascinating since it may be the first ever 'Carrilio' design (See Bugatti Trust Newsletter 9). Its fully machined shank has the H-shape generated by machining passes up the leading and trailing faces, giving a form where the 'H' is at 90° to that of a conventional forged rod. The result is easier to machine and gives better dynamic performance than the usual arrangement. Webs are just 1.25mm (50 thou) thick.

The crank looks much the same as that of any small single cylinder engine. Rather than the usual big end nuts it is held together either by a press fit or a cotter pin with a parallel locating head, which must have called for exceedingly precise fitting. A gear on the nose of the crank drives the central pinion train to the valves and accessories and also meshes with a gear serving the beautiful little multi-plate clutch and final drive worm. Substantial housings for clamps holding the engine to a bicycle frame are also part of the main casting.

After all these subtleties it's almost a relief to find conventional metric nuts. Perhaps Bugatti had lost the milling machine set up to produce nuts with a milled head and integral washer.

There are significant changes in the 72B version. Unfortunately the Trust drawings sets are incomplete and do not include a GA (general arrangement) drawing for either the T72 or T72B. The extent of the changes tells us that significant sums were spent on design and development but in the absence of solid evidence some guesswork is inevitable. The obvious alteration, since it is fully documented, is the 24mm bore. Stroke was maintained at 28mm. Before we laugh at this tiny bore increase it's worth remembering that it represents a 19% rise in capacity and presumably a torque increase of the same order.

There are significant changes to the main casting. Various parts, in particular the supercharger, are relocated and there are changes in the final drive. A more civilised lubrication system with a much improved oil pump and delivery mechanism replaces the T72 'spit and hope' and a dynamo on the end of the casting suggests that coil ignition may have been an option. In other words large scale change was adopted while keeping a useful proportion of the earlier parts.

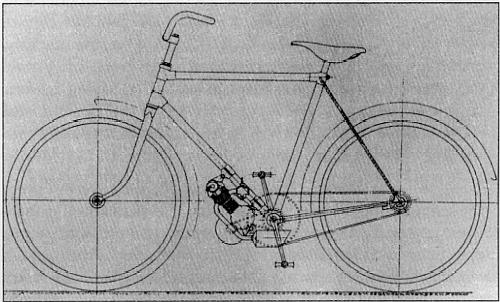

Never trust an artist's impression.

Various parts are omitted or hang in fresh air and the inclined

cylinder is probably mythical.

The illustration does, however show a crankcase and valve drive

casing

clearly intended for use with a crank set across the line of the

bicycle.

The big change seems from a study of the drawings and a rather unsatisfactory artist's impression to be the possibility that the later engine may have been installed with the crank axis across the frame rather than longitudinally and the gear-case on the right hand side of the engine. This would certainly have improved cooling on what was le Patron's first experience of a modern air cooled engine and would greatly simplify chain final drive to the rear hub. None of the drawings available make the final arrangement completely clear.

The most interesting recent development is the rediscovery on the back of a T73 detail drawing of a pencil sketch in Bugatti's personal style. This strongly suggests that the T73 engine was indeed mounted at 90° to the original arrangement. All that remains is to find a GA drawing or a surviving T72B - assuming that one was built.

The condition of various T72 engine parts at the Trust makes it clear that engines were at least bench run. A photograph of an intrepid Bugatti-propelied cyclist would be worth seeing. T72 detail drawings start in 1941 while 72B drawings are dated 1942 and 1943. This makes a guess of 1940 for the concept and first sketches reasonable. Test units were built in 1943 if not earlier but seem never to have reached the market. There is no clear evidence of how many were built but the Bugatti Trust T72 is stamped '7'.

There are at least two other surviving units, both T72. These appeared with a South of France collector who received a complete unit on a Peugeot bicycle, a separate complete unit and a 'vast box of bits'. The collection went to a second French collector, and Geoffrey St John in England was given access to the loose parts needed to build an engine. Through the kindness of the owner a complete engine was made available so that missing parts could be faithfully copied. The built up engine can now be seen in exploded form on long- term loan to the Bugatti Trust.

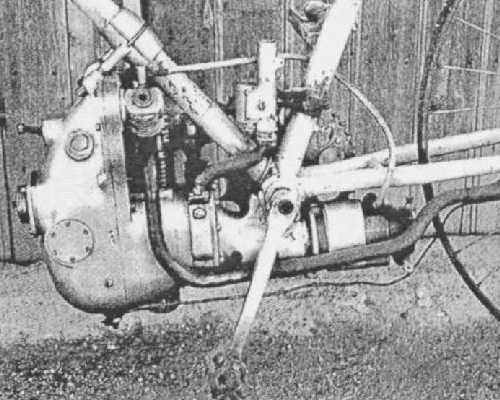

The complete engine on a Peugeot bicycle.

The two complete engines with their 'foreign' bicycle, plus the remaining loose parts after the St John/Trust engine had been built are now in the USA. There are rumours of an existing Bugatti bicycle which bears some similarity to the very clever Bugatti bicycle design produced by students as part of a successful co-operative scheme in engineering design innovation operated by Coventry University School of Engineering and the Trust.

This leaves three mysteries, one minor and the others fundamental. First, what did it weigh? The Trust engine is incomplete and uses a reproduction crankcase cast from the original and probably heavier. It may be possible to weigh a complete example but it is a safe bet that total installed weight will turn out to be more than that of a 50cc two-stroke Mini-Motor or equivalent[1].

Second, would it work? Richard Day of the Bugatti Trust has followed up references which suggest a peak rpm of 15,000, which is not unreasonable for the very light reciprocating parts involved. If we take 12,000 as maximum cruise it gives a top speed of about 30mph, which I know from experience is more than enough for bicycle brakes. Unfortunately we do not know the blower working pressure, which prevents us from calculating the BMEP and hence maximum bhp. More important, we can't work out a torque figure which would tell us if the machine with a reasonably light rider was capable of acceleration from a standing start through the gears to the putative top speed.

For comparison, the Honda 50cc racing four-stroke twin of 1964 with almost exactly the same stroke as the T72 could manage 15bhp at 19,000rpm, 300bhp/litre, giving a top speed of more than 100 mph. The most desperate 50cc two- stroke bikes overcome a ridiculously narrow power band (roughly 800rpm, from 13,200 to 14,000 rpm) with first a 12-speed box, then 18, achieved by putting a multispeed overdrive behind the main box. Both hands and feet were involved in gear changing, which hardly sounds the right sort of thing for going to the shops.

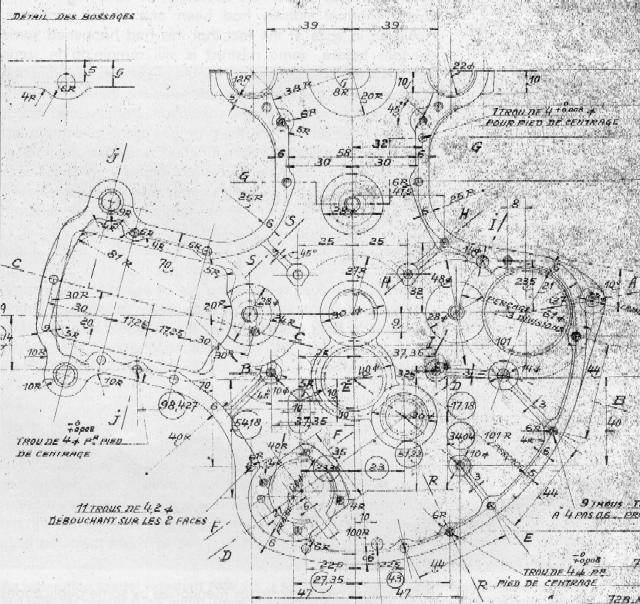

Jig-borer's nightmare.

T72B drawing of March 1943 shows the complexity of the main

gearcase.

It differs significantly from its earlier T72 equivalent.

The component is the main plate which forms

the frame for the gearcase with the bottom halves of the

two camshaft bearings on top.

The plate can be seen forward of the cylinder in the first

photograph.

This second (72B) version it shows a mysterious additional

structure at

about 10 o'clock, relative to the cylinder axis.

Finally, price. We shall never know, if only because of currency complications and retail margins and because it was never produced. The only certainty is that like a steam yacht, if you want to know the price you can't afford it.

Ettore Bugatti died in Neuilly in 1947 only months after Moisheim was legally returned to him.

The writer has tried to put the Type 72 Bugatti cyclemotor engine in the context of its time. He is most grateful to Richard Day of the Bugatti Trust for help, advice and access to drawings and to Geoffrey St John for additional details of the surviving unit on loan to the Trust.

[1] Interestingly, the two-stroke Mini-Motor was designed by Vincent Piatti who had worked in Bugatti's pre-war and wartime Paris design department after graduating as an engineer. At the end of the war he returned to Italy and created this really simple cyclemotor, ideal for post-war conditions there, which was later licence-built in England by Trojan. - Ed.

First published in Model Engine World, May 2002

With thanks to its editor - Andrew Nahum.