Essential oils are widely used in medicine, the food industry and perfumery. >From a modern point of view, they are produced from natural raw materials by a number of possible extraction processes [1]. The basic components of essential oils (EO) are hydrocarbons, aromatic derivatives, terpenes and their oxygenated derivatives (mono- and sesqui-terpenoids, alcohols and esters); less often in EO's we find the presence of diterpenes, paraffins, furocoumarins etc. Contrastingly, in EO and absolutes not derived from distillation, we find some virtually nonvolatile components (such as furanocoumarins in cold-pressed citrus oils, waxes and triterpenes in extracted oils, etc).

There is no universal standard for a concept of "EO quality", or yet an easily definable characteristic. Traditionally EO's have been assessed on the basis of individual requirements. A general approach to a formulation of normative requirements for EO's is absent - the way that EO's are assessed is dependent by virtue of its intended use. Physical characteristics of EO's - such, as density, optical rotation, solubility in ethanol-water mixes, boiling temperature, odour, color etc. - are easily measured. From our point of view the EO's have auxiliary, technological characteristics, which help manufacturers & perfumers to estimate the quality of EO's. However some maunufacturers do not provide the full identification of the components of the EO and consequently do not give a guarantee of authenticity, or estimate the influence of individual components on properties of the EO. Even considered with the data from the chemical analysis of the "basic" components, these are insufficient to characterize the quality of the EO.

EO quality is determined by a complex of technological and agrobiological factors, weather and geographical conditions of cultivation, duration of storage & the conditions thereof. There are some traditional ways of EO extraction to produce natural fragrant products (preferably water or steam distillation, but also extraction, enfleurage, mechanical pressing, etc.). The chemotype of the plant and the equipment used for oil extraction can determine the ratio of components in EO and also the proportion of undesirable impurities (furocoumarins, pesticides, etc.). Changes in density, optical rotation, etc. especially occur rapidly in the first few weeks after distillation/extraction of an EO. Some components (especially terpenoids) are very prone to isomerisation; esters may also be hydrolyzed during distillation and storage. Some components can oxidise in the presence of air.

Comparison of the published literature [2,3] with our own measurements (in Table 1. below), indicates that many samples of a given EO, range widely in composition, and frequently do not meet the standards declared in the certificate. At the same time, formal checks using the some of the older test methodology described in these standards, quite often successfully give the same results. Bu

t the demand for meaningful EO standards has increased, because

reproducibility of pharmacological effects is essentially determined by a parity

{ratio} of concentration of EO components. Thus, the recorded anti-microbial

effects of a given EO (determined by different researchers for a particular

microorganism), quite often differs by a magnitude of 2-5 times - simply because

the researchers often have not taken the EO composition into account.

t the demand for meaningful EO standards has increased, because

reproducibility of pharmacological effects is essentially determined by a parity

{ratio} of concentration of EO components. Thus, the recorded anti-microbial

effects of a given EO (determined by different researchers for a particular

microorganism), quite often differs by a magnitude of 2-5 times - simply because

the researchers often have not taken the EO composition into account.On the other hand, nowadays it is often a requirement to provide a chromatogram of an EO with 5-10 components identified with their appropriate concentrations, which should fall within given limits, and also to include the component ratios of certain specified items [4]. Differences in EO composition, usually not controllable at manufacture, can appear rather important at organoleptical control or, for example, in storage. The presence of traces of oxygen and water are also important as they can accelerate chain processes of polymerization and/or condensation of terpenoid components of the EO. In the presence of considerable amounts of oxygen, especially in conjunction with light or at increased temperatures, the tendency for peroxidation is amplified. Overall, within the EO, concentrations of aldehydes, acids, peroxides and oxides can accrue, resulting in the accelerated resinification of EO components. Under such conditions the physical, and more particularly, the biological properties of EO's are therefore changed [5]. This does not necessarily imply "deterioration" of the EO, - since in certain situations some modification of the properties can give positive pharmacological effect. But from the perfumer's point of view, or from the viewpoint of experts in the food-processing industry, "old" oils are inferior to fresh ones. It is obvious therefore, that the estimation of the quality of EO samples will vary, depending on the end use of the oil.

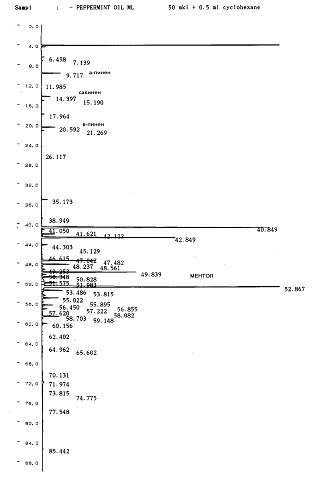

Unfortunately the specifications provided by the various bodies that regulate the quality of EO's, do not only serve technological aspects. They can, for example, indirectly influence the character of an export-import policy {politics} of nation-states, thus limiting competitive access to home market EO's into some regions. For example, the American standard on Mint EO's (MEO) contains rigid restrictions favouring high menthofuran contents. Manufacturers from Europe and Asia cannot meet these standards because of distinctions in cultivated peppermint chemotypes which have low menthofuran levels. According to our data, menthofuran concentrations in Ukrainian peppermint EO, as well as in other samples from European MEO, are almost always below the level required by the US standard; nevertheless this peppermint EO can be of good perfumery quality and possess standard pharmaceutical properties. We can therefore regard such standards as part of a complex of protectionist measures! By the American rules, products such as dementholised EO of Japanese mint Mentha arvensis should have the inscription "Cornmint", since these are considered as low grade goods [6]. Among identified components of a complex of volatile organic compounds (VOC) of MEO (see picture) the basic is l (-) menthol. Various grades of extraction of menthol receive the most types of MEO, and so requires target selection of Mentha plants strains. The menthol content in some samples of our mint oils that we have analysed (see Table 1, and [3]) varied between 25 up to 90 %. Mint EO contains about 15 basic components, not considering additional trace substances.

Table 1. The contents of some compounds in the peppermint oils