GWR 14xx CLASS - Kit SIX - Smokebox and Copper Pipework

The numbers in brackets refer to the item numbers on the parts list.

Kit 6 duly arrived on time. All the parts for the oil check valve to the steam chest were fitted without any problems.

The next task was to fix the smokebox hinges (DO60102) to the smokebox door (DO60101), together with the hinge blocks (DO60103) and door hinge pin (DO60104). No problems here. The door handle and smokebox dart were then assembled, it was here that the first problem arose. The tapped holes in the smokebox front (DO60114) were not deep enough for the bar bracket (DO60111) fixing holes. The smokebox front was returned to Winsons for rectification twice. They couldn't get it right on the third attempt, I eventually shortened the screws. The design of the smokebox door was such that its sealing with the smokebox front was on a 45 degree bevel. This necessitated much filing and emery rubbing to obtain a satisfactory seal.

The next item to fit was the smokebox saddle (DO60116). The design of this made sealing to the cylinder tops difficult, there being gaps at the front and back that needed to be filled in and material had to be removed from the bottom to fit.

The final task with the smokebox was to fit both the front and rear rings to the smokebox barrel. Both were a very tight fit.

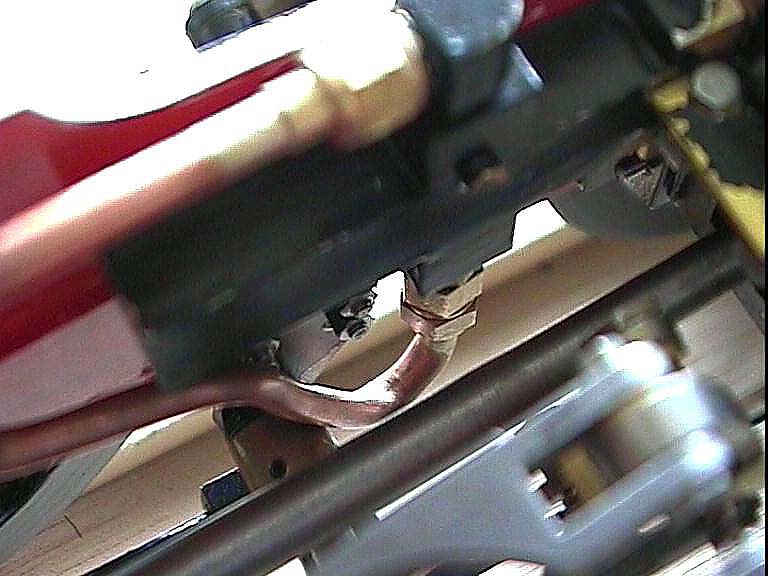

The running of the copper pipework proved a little arkward. The pipe from the steam chest to the lubricator (DO60125) was reasonably easy, but due to the route of the pipework some pre-bending was necessary. Once the top of the frames had been reached then in-situ bending could be carried out. The tank to pump pipework (DO60126) proved more troublesome in the area of the pump. The pipe had to bend quite sharply to clear the weighshaft. The remainder of the run and that of the pump to boiler pipe were straight forward.

Finally the sandboxes were fixed to the frames.

One final word about painting. I managed to knock up a fairly crude wooden turntable to ease the painting of round objects such as the smokebox. I have now resorted to spraying rather than brush work now that we are onto the more important parts from an appearance point of view.

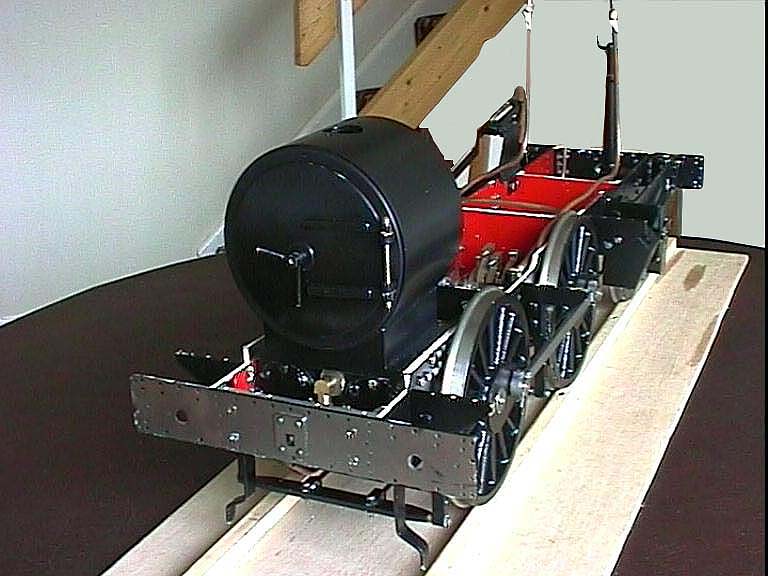

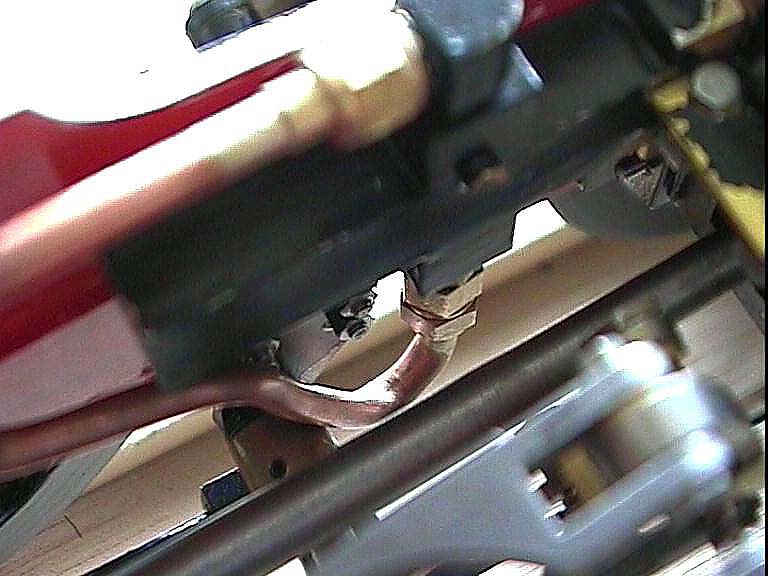

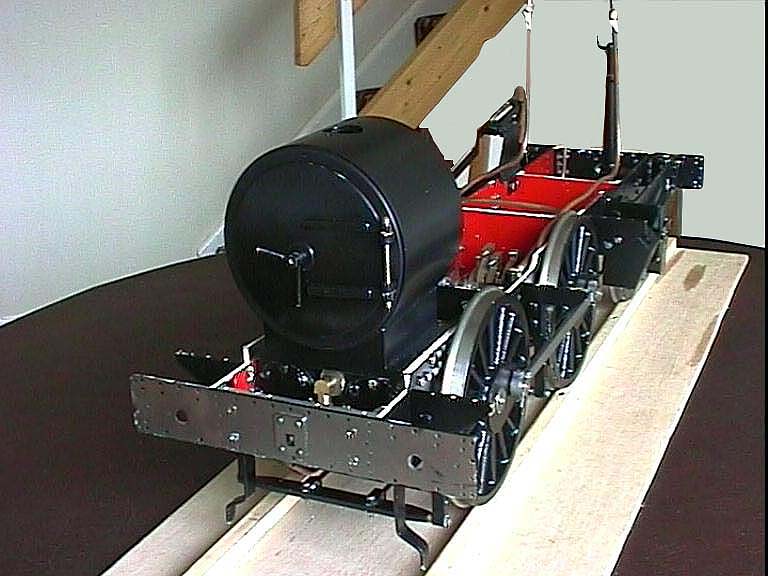

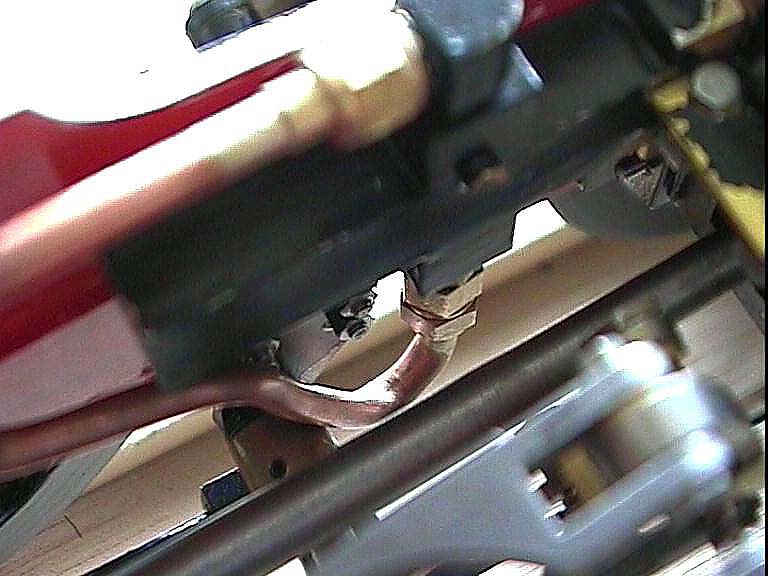

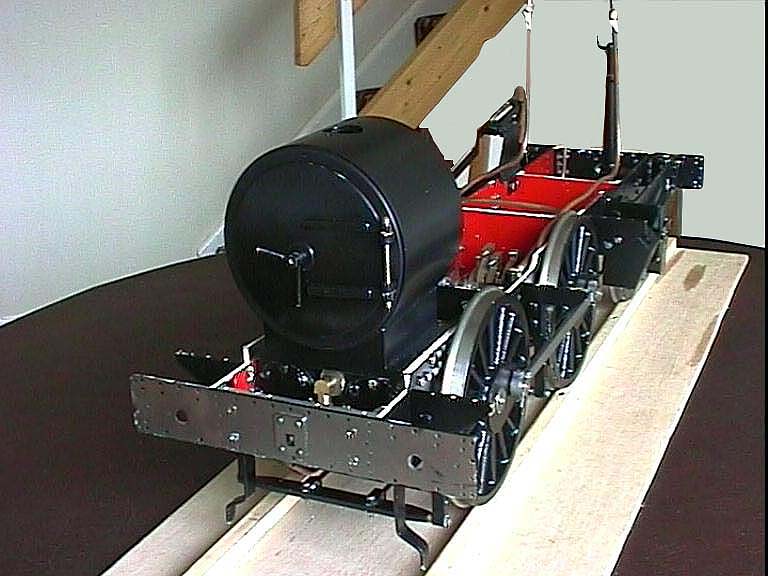

The photos below show the completed frames at stage 6 and the pipe bend from the bottom of the pump

Complete Frame at Stage 6 showing smokebox

Pipework at Pump showing bend to avoid Weighshaft

Click here to go to previous page (Brakes-kit five)