Go

to the Archive index

Go

to the Archive index |

RALEIGH

|

On 5th December 1957 a short news item in the Motor Cycle read:

‘Mopeds are being developed by Raleigh Industries, the famous cycle manufacturers. Prototypes are at present undergoing prolonged tests.’

Raleigh eventually made its debut as a moped manufacturer in October of 1958 with a machine bearing the not very original name of Raleigh Moped. Nowadays most enthusiasts refer to it by its model number - RM1 - to avoid confusion with other models from the Raleigh stable.

Raleigh's market research indicated that there was a considerable demand for a simple, low price machine and estimated a sales potential of 6,500,000 riders in Great Britain alone. The Raleigh Moped was certainly simple: it had no springing, no gearbox, it didn't even have a clutch. In appearance the frame was a normal straight tubed lady's bicycle frame although, of course, it was purpose-built with wide forks, internal stiffening and a special bottom bracket. It had no suspension at all, not even a spring fork. The Sturmey-Archer engine drove a pulley on the bottom bracket spindle via a V-belt. The secondary transmission from the bottom bracket to the rear wheel was by chain. There was also a pedalling chain and, unusually, both these chains were on the same side of the machine. There was no clutch - but a peg in the pulley could be withdrawn to disconnect the drive, allowing the rider to pedal the machine home when it broke down. Drum brakes (Sturmey-Archer again) were fitted front and back. Coils in the Lucas flywheel magneto provided power for the lights; and a dry battery pack, similar to that fitted to the Raleigh Superbe bicycle, powered parking lights.

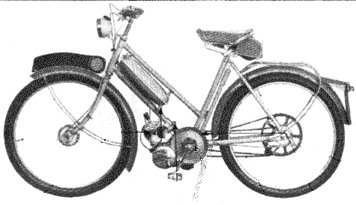

Nearside of Raleigh Moped (with fairings removed)

The Raleigh Moped was certainly a very solidly built machine. The frame was very sturdy and good attention had been paid to detail design. The combined front number-plate and tax disc holder was very neat. The rear carrier had curved stays which continued the line of the engine covers and also supported the rear mudguard; curved stays on the front mudguard continued this theme. The engine was built up from substantial castings and its Lucas 7F1 magneto-generator, although of a similar design to the well-known Wipac Series 90, was superior in having a steel centre which was securely riveted to the flywheel. The 26×2 tyres were carried on Endrick rims laced with single-butted spokes. A Raleigh RM1 would have to be severely mistreated before anything broke.

The engine design is interesting. Externally it appears a quite neat and original design, but internal examination reveals that the porting and combustion chamber shape are derived from the Trojan Mini-Motor. Although the engine carried the name Sturmey-Archer and Raleigh claimed it was "designed by Sturmey-Archer Technicians" it was in fact built for Raleigh by BSA and designed by the Italian engineer Vincenti Piatti. Piatti was the designer of the Mini-Motor and he reused this design for the Sturmey-Archer engine. Mechanically, the engine is quite different from the Mini-Motor but the piston, porting and combustion chamber designs are the same. This, of course, meant that from the outset the RM1 was saddled with an engine which was already 10 years out of date. A Mini-Motor will push a pedal-cycle along quite adequately but the additional weight and drag of the Moped with its fat 2 inch tyre was hard work for the Sturmey-Archer engine and performance was sluggish, especially at low revs. Things were improved a little when Raleigh started to fit clutches to the RM1 (a conversion kit was available for older models). This manual clutch made the RM1 awkward to ride - much better than the almost-impossible-to-ride clutch-less version. Being a manual clutch led to an excess of levers on the handlebars. To save the rider the problem of growing an extra arm, Raleigh fitted coupled brakes. The right hand lever operated two cables, one to each brake. The left hand brake lever was now not needed but was retained, operating the rear brake, thus complying with the legal requirement to have two independent braking systems.

So why wasn't the Raleigh a roaring success? The problem was probably in the market research. Its designers had produced the best machine to do the job they were asked to, but they were asked for the wrong thing. Perhaps Raleigh's idea of simplicity was different from the moped buying public's. The RM1 was mechanically simple but its continental rivals, although mechanically complex, were simpler to use. To the public simplicity did not mean not having a clutch, it meant having a clutch that you didn't have to operate manually.

However, Raleigh continued with the RM1 and several thousand were produced. They even brought out an RM2 - this had a large maroon fuel tank instead of a small grey one, otherwise it was much the same - but the end came in 1960 with the following announcement in October:

‘Following the success of the moped introduced two years ago, Raleighs are to extend their interests in powered machines ... Another new Raleigh will be a moped on the lines of the Mobylette under an arrangement with Motobécane of France.’

The RM4 Automatic and RM5 Supermatic (was there going to be an RM3?) were launched at the Earls Court show in November.

Several RM1s survive and they are becoming increasing popular with enthusiasts. They are a very well built machine and seem to be almost indestructible. My own, which had been unused for about 15 years when I bought it, only needed the tyres pumping up to get it running - it even ran on the 1967 vintage petrol still in the tank. Since then it has needed few spares: a new battery holder (the old one was corroded by the 15 year old batteries), a drive belt (readily obtainable) and rubber engine mountings (not so easy to find but easily fabricated from rubber tubing). The main problem encountered by RM1 owners is obtaining the engine covers if they are missing. MoTs can be interesting because of the coupled brakes (The trick is to de-adjust the rear brake cable on the coupled system so that most of the force on the right lever is transmitted to the front brake - it can always be readjusted after the MoT). It may be a pig to ride in traffic but it can cope more than adequately with the average cyclemotor run. It also provokes interest because it is one of very few models of all-British moped. One last tip: resist the temptation to ride Continental style with your feet on the engine covers - the pedals will fall off!

| Engine capacity | 49.9cc ( 38mm×44mm ) |

| Compression ratio | 6.2:1 |

| Maximum BHP | 1.3 at 4,300rpm |

| Ignition | Lucas 7F1 flywheel magneto generator |

| Contact breaker gap | .015in |

| Sparking plug | Lodge HH14 (Champion L5J) |

| Plug gap | .020in |

| Ignition advance | 5/32in BTDC |

| Carburettor | Amal 385/1 |

| Jet size | 40 |

| Overall gear ratio | 15:1 |

| Driving belt | Fenner A26 or A26R |

| Pedal gear ratio | 41.6in |

| Fuel capacity | 6.5 pints (includes 1/3 pint reserve) |

| Weight | 84 lb |

| Tyre size | 26in×2.00in |

| Front spokes | 32×14swg |

| Rear Spokes | 40×12/14swg single butted |

| Front Brake | Sturmer-Archer BFC |

| Rear Brake | Sturmey-Archer BRM |

| Headlamp | Lucas MCH64 |

| Taillamp | Lucas L590 |

| Main bulb | 6V 15W/15W |

| Pilot bulb | 3.5V .15A |

| Rear bulb | 6V 3W |

First published August 1989, revised March 1997