Go to the Archive index

Go to the Archive indexI have been privileged to see this report, which was lent to me by two of our members, the Smith brothers of Newbury (and many thanks to them). It covers the whole of the German motorcycle industry but I thought that you might be interested in those aspects of the report that deal specifically with two strokes. It gives an insight into the strength of the industry before the war and the state of things at the end. Those comments in quotes are lifted directly from the report.

'This investigation of the German Motorcycle Industry was undertaken to obtain certain specific information as well as to get an up-to-date picture of the industry and find out any interesting developments in progress since the beginning of the war.'

'Further information was desired by the (U.S.) Motorcycle Industry explaining the relatively big civilian production reputedly enjoyed by D.K.W. (Auto Union) and other manufacturers, and the high technical achievement of the German racing equipment made by BMW and NSU. The success of this equipment in international races in England and on the Continent was of special interest to American industry.'

'Since 1938 the German motorcycle design was strongly affected by three things: the Nazi plan for getting German goods into foreign markets, the shortage of automobile manufacturing manpower, and the shortage of motor fuel and materials.'

'The first force, the desire to get German goods into foreign markets, affected the international racing picture.' ... 'International competition on the continent was continued even as late as 1941 with the intention of keeping Germany in the lime light.'

'The shortage of automobile manufacturing manpower due to the army taking men, and the diversion to war industries made the motorcycle very important to everyday life'. Manufacturers lines thinned out to contain fewer models' ... 'so that tooling would produce more machines with less effort.'

'The shortage of motor fuel was important also. Shortages of materials such as steel made the small motorcycle quite important. The medium light two stroke machine far outsold all other models and the clean designs of late models produced by Triumph, Ardie, Victoria, Standard and others indicate keen competition of design from an appearance viewpoint.'

The Report then goes on to review each manufacturer in turn and the following extracts show those aspects which relate to two stroke machines. This section goes under the heading:

'SYMPOSIUM OF THE MOST IMPORTANT DESIGNS BY MANUFACTURER'

'This report does not discuss all of the models made in Germany, but includes those best known and most important. The cross section' ... 'is representative except that no information was available regarding the D.K.W. factory of Auto Union in Zochopau which is in the Russian occupied zone.'

(Because of this the writer of the report misses the one design that had the most influence on 2-stroke production in the UK and the USA—the DKW pre-war RT 125.)

1 'B.M.W.'

There is a large section here but nothing on two strokes.

2 'N.S.U. Vereinigte Fahrzeugwerkw A.G.'

Models just discontinued:

Model "Quick" 98 c.c. motorbike

Model 201 ZDB 198 c.c. light motorcycle.Models continuing the line:

Model 125 ZDB light motorcycle, 2 stroke with Wolf system of scavenging and flat top piston.'

(and various four strokes)

3. 'Zundapp-Werke - G.m.b.H. Nurnberg'

'Model DB 200. Displacement 198 c.c. Single cylinder flat top piston (Schneurle) unit power plant. Electrical system DC generator (on crank shaft) with ignition as unit (Noris) with battery.

Model DBX 250. Displacement 247 c.c. otherwise same as model DB 200.''Of the two smaller 2 stroke models, the 200 c.c. model well outsold all the others. The company produced over 200,000 of these in ten years. It sold better than the 250, and it is said that this is because in Germany an operator's license is not required for models of 200 c.c. and under.'

4. 'Victoria Werke S.G. Nurnberg'

'Victoria motorcycles produced before the war made up a line of six basic models. These included the "Saxonette" 60 c.c. motor wheel driven motorbike, two 98 c.c. models, a 150 c.c. model, a 200 c.c. model and a 250 c.c. sports model with "inverted" sports exhaust pipes.'

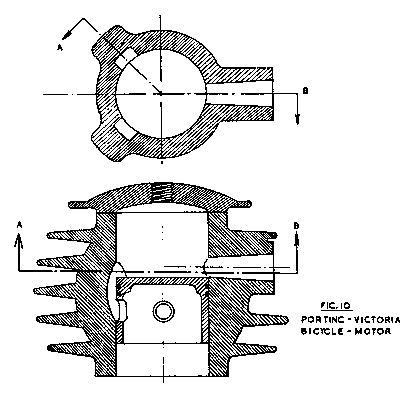

'The "Saxonette" motor wheel was purchased from the Fichtel & Sachs Company. This model was discontinued because it didn't go fast enough and cost too much. The Company is developing a neat little bicycle motor for attachment to any motorcycle. (This) is a 38.5 c.c. single cylinder 2 stroke with flat top piston of Victoria design, flywheel magneto, and with chain drive to rear wheel. The motor clamps to rear of frame next to the rear wheel.'

5. 'Ardie Werke A.G. Nurnberg'.

'In 1938 the Ardie Company listed 12 models in their line. These included three l00 c.c. models, four 125 c.c. models, four 200 c.c. models. The Ardie plant has been practically bombed out and catalogues and drawings of old models were not available. There was particular difficulty in obtaining the information wanted at this factory due to the disorganised condition here.'

'Each year after 1938 the number of models was decreased until the line in 1942 included only two items, a 125 c.c. motorcycle and a 125 c.c. stationary motor.'

'Model VF 125 has displacement of 123 c.c. two stroke with flat top piston in an aluminium cylinder, unit power plant. The clutch is placed on the engine drive shaft. A D.C. Noris generator is placed on the other end of the crankshaft and a battery is supplied.'

6. 'Standard Fahrzeugfabrik, Plochingen'

'This company has been producers of:

Small 3 wheeled trucks (watercooled)

Small 4 wheeled trucks (air cooled)

Two stroke and four stroke motorcycles

Power hand grain mowers.''The three wheeled trucks are front wheel drive. They employ twin cylinder 2 stroke motors made by ILO in Hamburg, with chain final drive to the front wheel. The entire engine and radiator are mounted on the unsprung front fork and swing when steering.'

The only 2 stroke from this firm was the

'2 cycle 250c.c. telescopic fork (no damping), 4 speed foot shift, hand operated center stand, flywheel generator charging battery.'

'The two cycle model is unique in construction in that it has a telescopic fork, grease lubricated with internal compression coil barrel springs. ... No damping is employed ... The saddle is mounted on a leaf spring coming back out of the gas tank tunnel, and incorporates a rubber saddle like BMW.'

7. 'Triumph Werke A.G. Nurnberg'

'The Triumph Company since 1939 have produced two models with 125 c.c. and the new 250 c.c. two stroke motors ... Since 1939, 1000 2 piston machines were produced for civilians and 12,000 for the Army. In normal times 10,000 to 15,000 per year were produced of the small 2 cycle model, this for 10 years.'

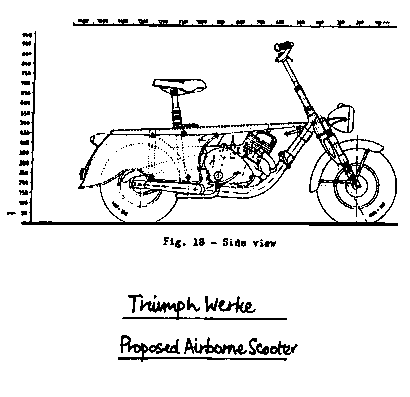

'Also of interest at Triumph were some designs that had not ever been in production. They are an eight piston two stroke, 4 combustion chamber air cooled Vee engine designed for the N.S.U caterpillar tractor, and an airborne scooter which was never built.'

The motor cycles were:

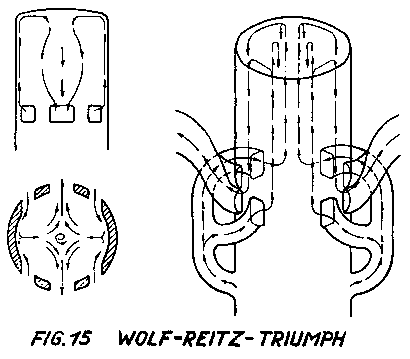

'Model B-125. A 125 c.c. 1 cylinder 2 stroke, single piston light motorcycle. The engine employs the Wolf "pitchfork" porting system with flat top piston.'

'Model B.C. 250, only produced since 1939, 248 c.c. double cylinder with single combustion chamber, employs a gear driven rotary inlet valve turning at crankshaft speed.'

'The airborne scooter was to be a knockdown affair, to use up a minimum of shipping space in transit.'

The outline specification was:

8. 'Steyr Daimler Puch A.G. Graz, Austria'

'This Company is the result of the Steyr Company refinancing the Daimler Co. and the Puch Motorcycle Co. The Company became Austria's only manufacturer of motorcycles. The motorcycle has been known for its use of the "uniflow" single combustion chamber double piston 2 stroke engine later used also by "Triumph" in Nurnburg.'

'The factories of this company contained 18,000 production machine tools, of which all but 5,000 were taken away by the Russians. It is claimed that in 1944 12,000 motorcycles were produced.'

'Model 125 has a displacement of 124 c.c. It is a 2 stroke double piston single combustion chamber design, petroil lubricated. A crankshaft mounted DC generator with battery ignition is used. The engine has one cylinder behind the other, the crankshaft turning in the same plane but in the opposite direction to the wheels.'

'Model 250 S4 has a displacement of 248 c.c. The engine is a two stroke double piston design with a common combustion chamber. It has a "Y" shaped connecting rod on one crank pin.

9. Fichtel & Sachs and ILO

'The Fichtel & Sachs Company made motorcycle engines and also ball bearings and clutches. It was because of this that many air raids were made against Schweinlurt, with resulting demolition of the plants including the motorcycle plant.'

'The ILO company had two plants, one in Hamburg and one in Pinneberg close by. The Hamburg plant has been pretty much damaged.'

Fichtel & Sachs engines include:

Model Saxonette a motor wheel for the Victoria Company

Model 74 c.c. Bicycle motor (2 versions)

Model 98 c.c. for motorcycles (2 versions).'ILO

'This company has produced motors as follows for the motorcycle industry:

Types F-60H and F-60R. Displacement 60 c.c. for attachment to ordinary motorcycles

Types FM 100 and FM 120K. These are 2 stroke 98 c.c. and 118 c.c. respectively.'

This concludes the review of manufacturers. The final sections may be of interest (if you have stuck with us so far).

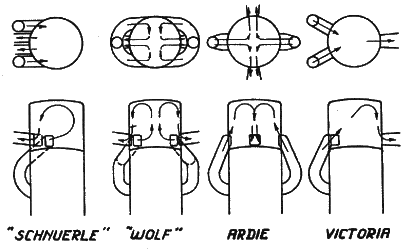

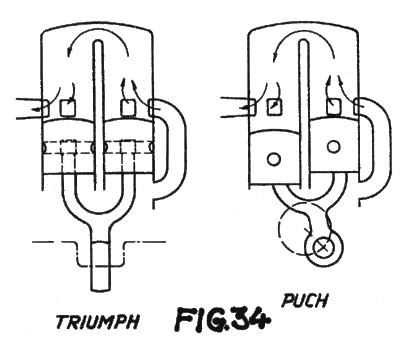

DISCUSSION OF 2 STROKE SCAVENGING METHODS

'There has been much effort in Germany devoted to research and development on scavenging systems for 2 stroke engines, both large diesel engines and smaller gasoline ones. One of the best known systems is the "Schneurle" flat top piston method developed since 1925 by Dr. Schneurle.'

'The Schneurle patents were so far reaching that much effort has been stimulated to "beat" them and this has produced several scavenging methods, they are:

1. Deflector piston scavenging

2. Schneurle flat top piston scavenging

3. Wolf "Pitchfork" scavenging as used by Triumph

4. 4 port as used by Ardie

5. The 3 port as used on the Victoria bicycle motor

6. 2 Piston uniflow (folded Junkers) design developed by Puch'

'The general purpose of the flat top piston is to avoid the poorly shaped combustion chamber and hot-spot arising from the deflector piston design.'

'From figures obtained, the 2 piston uniflow engines with common combustion chamber as used by Puch and Triumph give the best economy.'

'Since economy of manufacturing cost seems to be one of the primary purposes of using 2 stroke engines on motorcycles in Germany the rotary inlet valve is not used very much.'

There then follows a long section on the various attempts to find a design which does not come within the Schneurle patents. The final section of the report is:

LIMITATIONS OF INFORMATION OBTAINED DUE TO PRESENT CONDITIONS IN GERMANY

'The foregoing report is as complete as it could be made, taking into consideration the changes that war has imposed.'

'Very few production lines and factory layouts are still available for study, except as they were used for special military production. The dispersal policy has also resulted in shifting a great deal of the manufacturing into innumerable smaller companies. For example, BMW is claimed to have had over 50 dispersal plants.'

'The looting by slave labourers while the army was still in action against the enemy resulted in considerable loss of records. In many cases drawings and engineering records had been hidden in mines and caves for safety and the personnel remaining in the plants is unable to locate them.'

The report fizzles out at this point, drawing no final conclusions. The overall picture that I get is of a major industry before the war reduced to a hole and corner operation in tatters from trying to meet the demands of the German war effort. Everyone will find their own points of interest, I hope, but two things strike me:

Where are they now?

This article was first published in the January/February 2001 edition of The Independent, the magazine of the

British Two Stroke Club.