Go

to the Archive index

Go

to the Archive indexThe Cyclemaster power wheel made its first public appearance at the Utrecht Industries Fair in April 1950 but the story begins in 1948, just after World War II. A group of German engineers was sent to Den Haag in the Netherlands to work for HNG (Hart, Nibbrig & Greeve NV - importers of cars and motor cycles). They were to help with the development of a two-stroke car that had been designed by DKW in Chemnitze. A prototype was built by Pennock NV, Den Haag but, because of very high costs, this never went into production. In his briefcase, one of the Germans had a set of blueprints for a two-stroke bicycle motor that had the tank, engine and carburettor built into a wheel. This had been designed by DKW but never went into production because of the war. In turn, this DKW power wheel was derived from the Sachs Saxonette of the 1930s. This German was Bernhard Neumann (a designer from DKW). He got together with two other designers from HNG, Rinus Bruynzeel and Nico Groenerdijke, to study the blueprints. A prototype was made but, once again, high cost prevented the project going any further in the Netherlands. The engine proved to be very difficult to work on; you had to take it out of the bike every time you wanted to work on it. However, the three designers saw the possibility of using many of the parts from the DKW blueprints to make a different bicycle motor. They went ahead with this without saying anything to from HNG. When the new motor was ready they presented it to from HNG who had expected to see the DKW motor. Instead they saw a motor with tank, all mounted above the front wheel of a bike. The three engineers used the first two letters of each of their names to make up the name of the new engine: Bernard, Rinus and Nico—BeRiNi. The engine was also given the type number M13.

HNG began production of the new engine in November 1949. The first engines were 25.7cc, this was changed to 32cc in 1951.

Because the Germans were classed as prisoners-of-war, the DKW bicycle motor blueprints were placed in the hands of the Interpro Buro: an international organisation (English, American & French) that had been formed to help to build up industry in the Netherlands after the war. "Interpro Pats. Pend." is stamped on every Cyclemaster cover. HNG started a factory to build the M13 although many of the parts were made in England. The new factory was called the Pluvier Motorenfabriek.

Interpro sent the DKW blueprints to England; the German name on the blueprints was RadMeister, which translates as Cyclemaster. By June of 1950 the British version of the Cyclemaster had been launched. A company called Cyclemaster Ltd was formed at 26 Old Brompton Road, South Kensington, London to market the unit, which was manufactured by EMI Factories in Hayes, Middlesex. By this time the Cyclemaster had been re-styled into the familiar design which was to last, with only minor modifications, until production ceased. At its launch, the following technical specification was given:

| Capacity | 25.7cc |

| Bore & Stroke | 32 × 32 |

| Tank Capacity | 2.5 pints |

| Fuel | 25:1 petrol/SAE20 oil |

| Plug | KLG F50 |

| Gear Ratio | 18:1 |

| Weight | 33lbs |

| Max Power | 0.6bhp @ 3,700rpm (15mph) |

| Max Torque | 0.9ft lb @ 3000rpm |

| Cruising Speed | 18mph to 20mph |

| Fuel Consumption | 300mpg @ 18mph |

| Price | £25 including fitting |

| Carburettor | Amal 308 |

| Magneto | Wico-Pacy Bantamag |

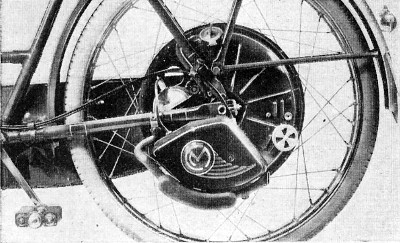

First version of the Cyclemaster

The Cyclemaster wheel sold in the Netherlands for the equivalent of £27 or, for about £38, it was available in a special frame with a rubber-sprung bottom-link front fork. Just like the M13, the first engines were 25.7cc and later 32cc; the type number was M14. The Pluvier factory never made any engine parts or bikes; these were made by other factories, Cyclemaster Ltd for example. What is sometimes called the "Dutch Cyclemaster" is, in fact, the very first model. This had no hub brake, a Bantamag ignition and an Amal carburettor; the magneto cover had a "CM" logo with curved lines and no "Cyclemaster Made in England" plate. The side cover had two holes: one for the tap and one for the filter, the fuel tank had radial ribs. The bicycle was made in Germany by Rabeneick; the wheels, head lamp, rear lamp and saddle came from Holland. Cylinder capacity was 25.7cc in 1950. One year later this was changed to 32cc—still with the Bantamag and Amal carburettor but now the magneto cover had straight lines and a "Cyclemaster Made in England" plate.

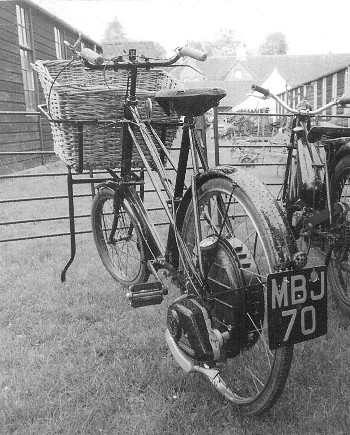

1951 Cyclemaster

The very first version of the Cyclemaster was never commercially available in Britain. All British 25.7cc Cyclemasters have the later "straight-line" styling, whereas machines intended for Holland retained the earlier "curved line" styling until the cylinder capacity was increased in 1951.

In its first year on the British market the Cyclemaster was in competition with nine other cyclemotor units (ten if one includes the VéloSoleX); however, it did have several advantages over the others: it was one of the neatest designs. With the exception of the controls and cables the entire machine was in one unit and fitting a Cyclemaster was not much more difficult than fitting a normal back wheel. There were no extras like fuel tanks, sprockets or pulleys to bolt on and it did not require any modification to the cycle (eg: sawing mudguards). Despite being the smallest capacity cyclemotor on the British market (the 18cc Lohmann was not available in Britain at the time) it would out-perform many of its rivals, thanks to its efficient engine design with a flat-top piston and rotary inlet valve. Being fitted with a clutch it was easier to control in traffic than fixed-engine machines.

The Cyclemaster exhibited at the Cycle and Motor Cycle Show at Earls Court in November 1951 incorporated the new feature of a coaster brake in the hub. This improvement had two advantages over a rim brake: it was more efficient (Cyclemaster rims often become contaminated with oil, impairing the efficacy of a rim brake) and it left the rider's left hand free to operate the clutch when stopping. The Cyclemaster now cost £27 10s - the price had gone up in August 1951 - and Cyclemaster Ltd had moved to 38a St George's Drive, Victoria, London. Although production Cyclemasters were painted black with a red "CM" symbol on the magneto cover, the model exhibited at the 1951 show was finished in silver-grey - a portent of things to come. The Cyclemasters sold in Britain were still 25.7cc models despite the fact that 32cc engine parts were being made for the Netherlands.

By April 1952 Cyclemaster Ltd was advertising the fact that it had sold over 50,000 units in Britain.

1952 saw several changes to the Cyclemaster: the capacity was now increased to 32cc, there were styling changes to the tank and carburettor cover, the magneto was changed to one with lighting coils and the black colour scheme was changed to "polychromatic grey" with red ribs on the tank and carburettor cover. The magneto fitted was the Wipac Migemag - the Series 90 MkI. Despite all these changes the price remained at £27 10s.

Cyclemaster's publicity was not as up-to-date as the actual machines: at the end of 1952 the advertisements still showed a picture of the 25.7cc model.

Cyclemaster advert, November 1952

UK production had passed the 100,000 mark by the end of the year. The 100,000th unit was finished under the watchful eyes of the Chairman of EMI and three directors of Cyclemaster Ltd - a photograph of the event appearing in the weekly motor cycle magazines.

The Cyclemaster would now only have minor detail changes for the rest of its production; the most significant of these happened in 1953. At this year's Cycle and Motor Cycle Show the Cyclemaster was exhibited with a new carburettor which had been developed by the Bletchley Engineering Co Ltd. BEC had collaborated closely with Cyclemaster in developing this carburettor but the agreement did not give Cyclemaster exclusive rights to it. BEC carburettors were also used by Sinclair-Goddard for their Power Pak cyclemotor, and on some of the small industrial engines produced by Vincent.

Although not strictly within the scope of this article, mention must be made here of the Cyclemate. This was launched by Cyclemaster at the 1954 show and consisted of a slightly modified Cyclemaster engine mounted ahead of the bottom bracket on a mixte type cycle specially built for the purpose by Norman Cycles of Ashford, Kent. This was an attempt by Cyclemaster to break into the moped market. Sales of mopeds were rapidly increasing and taking over from cyclemotors but the Cyclemate was not destined to reach the heights of popularity gained by the Cyclemaster.

On 24th January 1955 the Government closed a loophole in the law and imposed a 25% Purchase Tax on cyclemotors. Until this time a cyclemotor unit was not subject to Purchase Tax provided it was bought separately from the cycle it was to be fitted to. To combat the effect of this tax the basic price of the Cyclemaster wheel was dropped to £26 8s giving a total price of £33. During the year the price was dropped further: first to £32 13s 11d and then to £29 19s 2d (£24 15s 3d basic), but by the time of the London Show in November 1955 the price was going back up again, standing at £30 18s 3d.

Cyclemaster Ltd separated from EMI during this year. Both the manufacturing and the office were moved to Tudor Works in Chertsey Road, Byfleet, Weybridge, Surrey. Early in 1956 the sales office moved back to London—to 154 Shepherds Bush Road.

By now the cyclemotor market was beginning to dwindle. In 1957 the Cyclemaster was one of only six makes of cyclemotor available whereas potential customers could choose from 32 makes of moped. Cyclemaster Ltd diversified its business to reflect this change in the market. In addition to the Cyclemaster and Cyclemate they included the Berini M22 moped and the Piatti scooter in their range of machines. During February 1957 the price of Cyclemasters dropped again to £25 0s 6d. The Shepherds Bush office closed in August 1957 and moved back to the Tudor Works.

These were tough times for Cyclemaster: there were creditors meetings in December 1957 and January 1958. A rescue package had been proposed at the December meeting but, despite this, it was decided at the January 1958 meeting that Cyclemaster would go into voluntary liquidation.

A new company, Planloc Engineering, was formed in March 1958 to buy the remains of the Cyclemaster business. Planloc continued the production of the Cyclemaster, Cyclemate and Piatti from Tudor Works. By 1960 Cyclemaster had been taken over again, this time by by Britax (London) Ltd. Production remained at Byfleet but the Tudor Works was now called Proctor Works. The Cyclemaster was now selling at £29 11s 3d with only the Itom and the Power Pak still competing in the cyclemotor market. The demand for cyclemotors had now all but vanished and marketing of all three of these machines ceased in 1961.

In Germany Rabeneick made their own version of the Cyclemaster, starting in 1952. It used the same bike as in Dutch machines but with German headlamp, rear lamp and saddle. The capacity was 32cc and the magneto cover had straight lines and a "Cyclemaster" name plate (but saying "Made in Germany" instead of "Made in England"). A Rabeneick logo was carried on the cover instead of the CM logo. Ignition was by Bosch. Some Rabeneick Cyclemasters had Wipac ignition; these ones have a magneto cover with a CM logo. The side cover had just one hole for the tap; the carburettor was a float-less Meco with its filter on the inside. The cover was held in place by four screws. The option of a conventional Amal carburettor was available. The silencer had a detachable side cover held in place by two screws. This was to make cleaning easier. Like HNG, Rabeneick used the model number M14. This version of the Cyclemaster was also marketed under the name "Taxi".

In 1954 Rabeneick made their own version of the Cyclemate; this was called the M53. Unlike the Norman Cyclemate, this had belt drive instead of chain. The engine used Bosch ignition and, therefore, a magneto cover with the Rabeneick logo. The float-less Meco carburettor was used on this machine too.

In the Netherlands there were other variants of the original Berini/Cyclemaster engine. Type number M15 was the BoatMaster, an outboard motor suitable for small boats. Type M16 was the LandMaster, a stationary engine. Very little is known about the LandMaster and it is extremely rare.

In 1952 HNG produced the CycleStar, type number M19. The 32cc engine was also developed from the DKW blueprints and uses many of the same parts as the M13 & M14. The engine fits under the bottom bracket and uses a roller drive to the rear wheel. The CycleStar had a spring fork using rubber bands and short leading links.

Another rare Dutch model is the Cyclemaster de Luxe. It was made in 1956 for one year only and consists of a normal Cyclemaster wheel mounted in the CycleStar spring-fork frame.

Another version of the Cyclemaster, based on the Rabeneick Taxi was made in Switzerland by Motosacoche and there was a pirate version produced by Flying Pigeon in the People's Republic of China.