Go to the Archive

index

Go to the Archive

indexThe report by A Pattle concerning his Cyclaid (September Journal) prompts me to write a few notes on this little device. British Salmson Aero Engines Ltd. had commenced operations in the early thirties, at Raynes Park, London, SW20, manufacturing, under licence, initially, a small radial aero engine, and from 1934 to 1938, the British Salmson car. At the same time general engineering subcontract work, to the highest standards, was undertaken, mainly in the aeronautical field. Needless to say, in wartime the firm expanded and was very busy indeed.

After hostilities had ceased, general subcontract work continued (including at one point, the machining of a batch of Vincent vee-twin crankcases), but in the early fifties, the company's fortunes declined, and the works passed into the hands of D Napier & Sons, the aero engine builders in nearby Acton. The principal British Salmson directors registered a new company, British Salmson Cyclaid Ltd, with an office at 76 Victoria Street, London, SW1 - but they no longer had any capacity to manufacture.

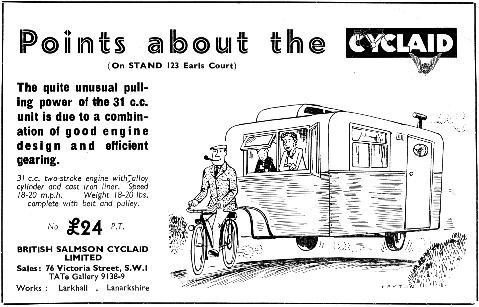

A licence was purchased to manufacture the Cyclaid - a 31cc 3/4bhp cycle motor attachment to an ordinary pedal cycle. This was, in fact, a German design. Indeed, the first 200 engines sold had "German type castings" and Bosch magnetos (the Wipac Bantamag was used on wholly British production).

The Company was not deterred, however, from stating "The Cyclaid power unit is British designed and built throughout, to precision limits". There is some evidence to suggest that initial manufacture was carried out by Napiers in the former British Salmson factory, but the bulk of production was undertaken on an industrial estate at Larkhall, in Lanarkshire, Scotland. The address was actually quoted as British Salmson Cyclaid, Larkhall, but in fact the manufacture of such parts as were not bought out, and the assembly work, was carried out under subcontract there.

The magazine "Power and Pedal" gave a good report of the Cyclaid, stating that low speed pulling was the best they had encountered (helped by belt drive and sprung rear engine mounting). Gearing was low, needless to say, with maximum speed just under 20mph. LPA was hardly ever required; however, the whole device was very vintage, both in conception and appearance, a rim for the V belt being clipped to the spokes of the rear wheel.

Price initially was £19; subsequently, removal of purchase tax on clip-ons reduced this to £15. Within its limits, it was a good little machine, well engineered, quiet, very flexible, and perhaps, most importantly, light in weight. The belt rim drive, of course, enabled the rider to make use of his hub gears in the usual way.

Sales were quite good for the first year or two but I believe purchase tax was re-imposed around 1955/56, and this killed sales stone dead.

Rather surprisingly, quite a lot of the original paperwork involved in getting the project underway has survived, and is in my possession. There are machining instructions (in German, with hand-written translation), hand-written parts lists and schedules of materials for ordering, costing sheets for each part, advertising copy and photos, letters and calling cards from would-be suppliers, etc, etc. For those who, like me, approve of belt drive, it is satisfying to note that Messrs Ferodo, Fenner, Brammer, and Gandy were all anxious to supply the company with their product.

From the evidence in the files, it appears that 6,000 sets of components were ordered initially. Subsequent costings show that consideration was being given to ordering a further 6,000 sets. There is a reference to sales of 2,700 units having been achieved, but the date is not given.

I wonder how many survive?

[This article first appeared in the November 1992 VMCC Journal and is reproduced by permission of the author]