Go

to the Archive index

Go

to the Archive index(Date unknown)

The drive is direct—no clutch. The sprocket on engine has ten teeth—the large ring sprocket has approximately 80 teeth—I got tired counting them. The engine sprocket is located between the flywheel and the crankcase.

There are three controls: a ratio of 1 to 8 throttle, a choke connection, and very important a control to a rod on engine which did two things—it grounded ignition to [the] spark plugs and activated [a] relief valve in each cylinder. To start [the] engine, [the] bicycle was pedalled with [the] lever in [the] pre-start position, no ignition and relief valves open (choke closed for cold engine). When [the] engine was turning over, [the] lever was activated. This brought [a] spark to [the] plugs; [the] relief valve [was] closed, and happily the rider was on his way under power. Since traffic lights were few or non-existent, it wasn’t too much of a problem that [the] engine had to stop every time [the] bicycle came to a stop (direct drive gear to gear by chain). To stop, [the] control [was] lever activated, spark grounded - compression released. To start, [the] procedure as above but [the] choke of course [was] not needed for [a] warm engine. All this above is surmised since I never have actually operated [the] engine and I am certainly willing to be corrected if wrong. I may some day, when more time is available, actually try to see if I can get it running.

As the very excellent article in January ’79, TAO states, 17,000 of these bicycle units were sold but with Ford’s car selling for $365.00 it was only natural that the bicycle motor business could not thrive forever.

However, we can be most thankful that this basic little engine could be used to develop that revolutionary, grand little outboard motor which appeared in 1921. I have to admit that, as in the past, even today my pulse quickens just a bit when I see one of those early little 2HP Johnson outboards. There are still quite a few of them around—many of them in running condition even now.

Is there anything that brings one more quickly to attention than an advertisernent that states engine in original crate with instruction book and parts list?

Johnson cyclemotor

… talking of early unusual engines, we have had a teeny weeny flat-twin two stroke, as used in the Economic motor cycle of 1920-ish, kicking about … literally … at Stanford Hall for some years. I can’t remember who gave it to John Griffith for exhibition but wherever it was put, someone fell over it, so the other day I decided it was really so unusual (I have never seen another since the day I rode one … or tried to) that it deserved to be displayed properly. Curiosity overcame me so, I dismantled it.

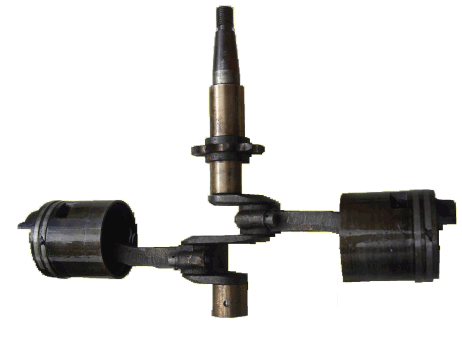

A moment’s work really because it was designed to be dismantled with only one tool, a screwdriver. That beats the Wooler that could I seem to remember be dismantled with just two spanners. The cylinder head castings met on the line of the crankshaft, trapping the PB.bushes in between, and the really staggering bit was that the split big ends were held together by more of the same size of cheese head screw... wire locked in this case, thank goodness. The con-rods were cast in phosphor bronze, so no liners were necessary and were cranked so that the cylinders could be in line. The thing operated on the same principle as the Viceroy scooter made by... no, I will not bring more shame upon a greatly revered marque. Both cylinders fired at the same time (or were expected to) driving the pistons towards each other. This eliminates vibration (when they manage to fire together) but makes a noise like a single.

The Economic Engineering Co of Eynsham in Kent tried hard to use up these engines which were US Army surplus chore horses for driving trench pumps and dynamos in the 1914-18 war. There was the motorbike which was like a miniature Sopwith ABC, a pedal cycle attachment and a buckboard... four wheels and a plank more or less. I reckon if you went down there with a metal detector you might find another. Meanwhile, at Stanford Hall, you could see this and one or two other things that no other museum has.

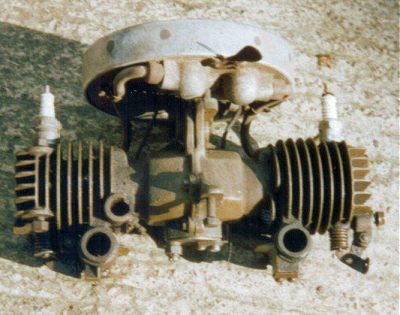

An Economic engine

Dear Mr. Hornby,

There is a chap who writes in Stationary Engine magazine, called Kim Siddorn, who some time ago found a small flat twin two-stroke engine which at the time he was unable to identify. He has just found out that it is called ‘The Economic’ and that its design dates from the Great War. He has also found out that it was made by AMC and that after the war it was used for an American autocycle called the Johnson. This is to ask if any NACC members have any info on the Johnson, could they please let Kim know; his e-mail address is kim.siddorn@blueyonder.co.uk. Also enclosed are a couple of photos from Kim’s own website http://community.webshots.com/user/kimsiddorn, one is of his engine and the other is of the rear end of a Johnson autocycle. All the best.

Yours,

Christopher Wigdor

[See article on the Johnson/Economic in Marque Time. Three pictures of Kim’s engine appeared in the October 2002 Stationary Engine - Paul]

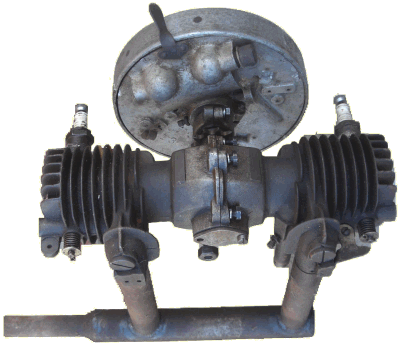

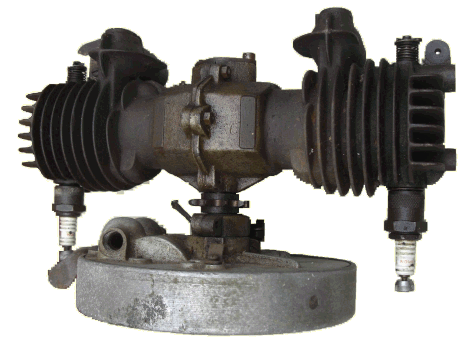

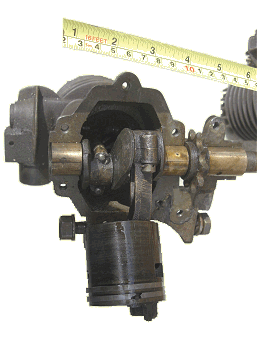

Two pictures of Kim Siddorn’s Economic engine

I wrote this article a few years ago and am prompted to publish it as a result of Christopher Wigdor’s letter elsewhere in this issue. If any member has any further history on the Johnson/Economic, please write in.

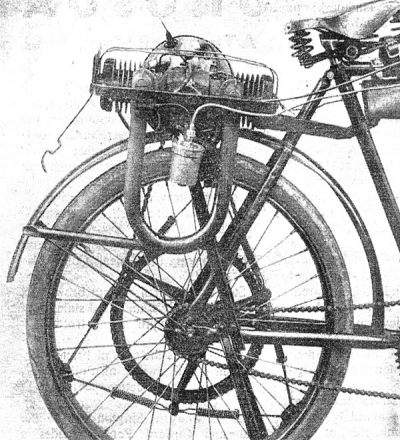

Marketed as the Johnson Motor Wheel, the Johnson cyclemotor is a flat twin two-stroke stated to be of 154cc; it fits over the rear wheel of the cycle, which it drives by chain to a sprocket fitted to a special rear wheel that was included with the cyclemotor kit.

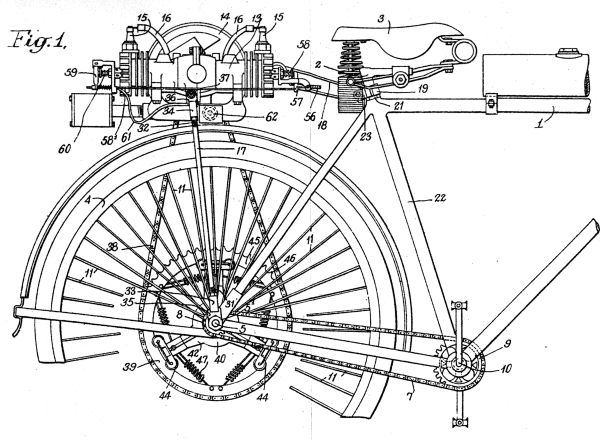

The Johnson was patented in the USA in 1919 and in the UK in 1920, by Louis Johnson of East South Street, South Bend, Indiana, USA. It has a flywheel magneto on the left hand side of the cycle, and between the magneto and the crankcase there is a chain sprocket which powers the rear wheel. The tank is fitted on top of the cross bar, with a gravity feed to the carburettor, which is located on the right of, and below the engine.

The British Economic cyclemotor of 1921

The unit has a distinctive ‘U’ shaped exhaust pipe fitted to the two cylinders, on the right hand side of the cycle. This is at variance with the patent drawings. As manufactured, the special rear wheel also differed from the patent specification. The engine driven chain sprocket is suspended in position by six springs attached to three bosses on the rim of the wheel, and by three substantial hinged spokes attached to the hub, and this design was stated to absorb the vibration and torque from the engine and prevent it being transmitted to the cycle and rider.

Evidently quite a successful unit in North America, the Johnson was built under licence in Great Britain as the ‘Economic’, by Victor Motors (Eynsford) Ltd, of Eynsford, Kent, and marketed by Economic Motors Ltd.

One of the patent drawings

The Economic was fitted with a Capac carburettor. As well as direct sales for the cyclemotor market, and use of the engine in the Economic cyclecar, the engine was sold as a proprietary engine to some of the ephemeral vehicle manufacturers who briefly traded in post-Great War Britain. It is known to have been used in the three-wheel, single-seater Cambro cyclecar, and the Mohawk autocycle, and may have been sold for industrial use too.

The Economic is believed to have been built in 154cc and 165cc versions, the latter having a bore of 52mm and stroke of 38mm. One or two Economics are owned by members in the Club.

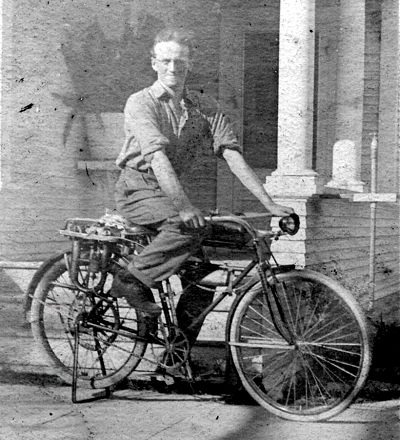

‘Clarence and his Wheel, just the colour of tomatoes’

a Canadian snapshot from the 1920s.

You asked for any more info on the Johnson/Economic bikes; herewith my two penn’orth from what I laughingly refer to as my filing system (my wife has another, less flattering, term for it).

Johnson was registered as WTT Engineering Co, 6-10 Dalling Road Hammersmith. It was featured in the Motor Cycle of Nov 27th 1919 and Classic Motor Cycle, April 1984 (for some reason I have a question mark against the latter in my notes but can’t remember why!)

Economic 1921-23, listed as the Eynsford Engineering Co of 741½ (curious, that half) Wells Street, London W1. Featured in Motor Cycling Nov 29th, 1922. Also Classic Motor Cycle Dec ’83, page 50. VMCC Journal Aug ’90, page 358 and photo in VMCC Journal of 1981 page 168. My notes also suggest that the engine’s origins lay in US Army surplus whence they were utilised as trench pumps (essential on the Western Front), powering dynamos, etc. Hope this is of some use.

The engine was indeed, as stated, ‘quite a successful unit’, not only in North America, but world-wide, it being the basis of the famous Johnson Outboard motor, and designed for this purpose. The Johnson, along with the similar Evinrude, created and held this market for many years.

The simple and effective twin-cylinder layout would have been chosen for its even torque and hence, quiet and smooth running at moderate throttle openings - desirable characteristics for both marine and powered cycle applications! A further advantage, important when on the water, would have been that two plugs would have had to whisker before the engine failed. The writer is not certain if the early Johnson marine units were air or water cooled, but suspects the former, which does have definite practical advantages.

Reference to a calculator indicates that the engine’s bore and stroke were, as was standard American practice, measured in inches. Thus 2"×1½" [50.8mm×38.1mm] gives 154.5cc: an overbore to 2 1/16" [52.4mm] increases the capacity to 164cc as stated. The bore/stroke ratio [1.375:1] then becomes quite exceptional and confirms that over-square engines were well understood (and widely utilised both here and in America) in early days. One very good reason for the use of such an extreme ratio in this application would have been to keep the length of the power unit as compact as possible. This would have to be weighed (literally!) however, against the need for the rather heavier flywheel required, to aid both low speed running and pulling and, moreover, to provide extra inertia for hand starting purposes - a short stroke inhibits an engine’s ability to draw in a good charge of mixture at this point, and a good prolonged spin is required. This is the main reason why certain modern lawnmower engines feature electric starting, by the way.

A close study of the engine crankcase as installed on the Economic cyclecar indicates a lozenge shaped plate bolted thereto. It is positioned over both horizontal and vertical crankshaft centre lines. This would have been replaced, no doubt, for marine use by a suitable bearing housing for the output shaft to the propeller. Incorporation of this design feature does therefore imply that if indeed this interesting and successful little engine was in fact manufactured in the UK, as opposed to being merely imported, then its sponsors in this country did intend it to be suitable for a variety of purposes. For cyclemotor use the engine is on its side. It is unlikely however that American licences would have permitted the use of UK manufactured engines for outboard motors to compete with their own product.

Perhaps one of the current owners of an Economic Motor Wheel will break cover and tell us whether or not the screw threads are to Imperial or AF threads? Also, is the magneto of UK or US manufacture? The reference to Victor Motors [Eynsford] is interesting. What was probably the first British cyclecar, constructed in 1906, by Harold Dew, originated here. A company was duly formed to manufacture cyclecars, but not engines. However, Dew left the company, and in 1914 it changed its name to Victor Motors Ltd and transferred its manufacturing activities from Eynsford to an address in Ealing, West London. A subsequent reversion to an address back in Eynsford does lead one to query the actual source of manufacture of the Economic engine.

Concerning the special rear wheel suppied with the engines, that shown in the photograph does indeed differ somewhat in design, but not in principle, from that shown in the patent application drawing. In both cases, what we would now call a spring loaded cush drive is provided, its function being to absorb chain transmission snatch when the throttle is opened or closed. The production version appears to be a stronger design with the potential for use of heavier springs to control sprocket movement.

Given the low power output of this engine, surely not more than 4bhp, one wonders why a chain rather than a link belt, with its inherent flexibility, was employed? One possibility is that the available space between the magneto stator plate and the crankcase wall would only accommodate the width of a sprocket rather than a pulley. It was probably necessary to take the driving loads on this side of the crankcase on account of the location here of the heaviest, or possibly the only, main bearing.

In conclusion, it should be pointed out that the Economic three-wheel cyclecar was stated to weigh 150lbs and achieve 30mph, which taking account of the driver’s weight, is quite creditable. Owners of a Johnson or Economic Motor Wheel equipped cycle should therefore be able to expect a sparkling performance!

A footnote or two to my previous article. The reference to Victor Motors [Eynsford] Ltd and Economic Motors Ltd, and the use of the Capac carburettor, were taken from a description of Mark James’s Economic in the October 1992 Buzzing. The British patent number is 139303 and the US patent numbers are 1257711 and 1257712. The Motor Cycle magazine for 17 April 1924 states that the Economic was manufactured in 1922/3, was 165cc, with a bore of 52mm and stroke of 38cc.

Some pictures from Robert Swade of another Economic/Johnson engine:

This one doesn’t have the U-shaped exhaust so may have been used for something other than a cyclemotor. Bore & stroke of this unit are 2" × 1 9/16", giving a capacity of just over 160cc.